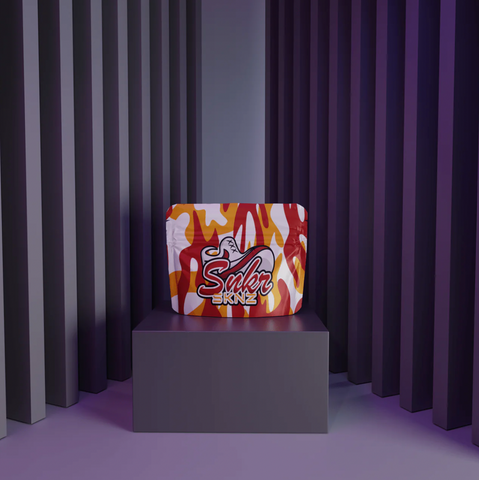

Embark on a journey into the realm of custom Mylar bags, where practical packaging meets personalized branding. In today's competitive marketplace, the packaging is not just a protective shell; it's a canvas for your brand's story. Custom printed Mylar bags have emerged as a versatile and robust option for businesses looking to make a lasting impression.

This comprehensive guide will walk you through the nuances of printing on Mylar, branding with your logo, understanding the ideal thickness for durability, and decoding the significance of 'mil' in Mylar bag specifications.

Can You Print on Mylar Bags?

Yes, you can absolutely print on Mylar bags! It’s a process where technology meets creativity, turning these sturdy bags into brand ambassadors. Modern printing techniques can lay down vivid, sharp designs that catch the eye and engage the customer. Whether it's intricate patterns, bold logos, or detailed product information, printing on Mylar bags is a strategic way to elevate brand visibility.

Techniques to Know:

- Digital Printing: Perfect for detailed, multi-colored designs on smaller batches.

- Flexography: A go-to for larger orders, flexography offers efficiency and consistency.

Factors to Consider:

- Image Quality: Ensure your designs are crisp and clear for optimal transfer onto Mylar.

- Color Precision: Colors can vary on Mylar material, so a test run might be essential.

- Print Longevity: Choose inks and printing methods that ensure your design endures handling and storage conditions.

How Do I Put My Logo on a Mylar Bag?

Incorporating your logo onto a Mylar bag is like signing your masterpiece. The process is typically streamlined and managed by the printing company, but it involves key steps:

Steps to Branding:

- Artwork Submission: Provide your logo in a high-resolution format, like vector files, for clarity and scalability.

- Specify Your Vision: Clearly communicate where and how large you want your logo on the bag.

Proof and Confirmation:

- Examine the Proof: Review the mock-up to ensure every detail aligns with your vision.

- Green Light for Production: Once satisfied, give the thumbs up to let the magic happen.

What Thickness is Best for Mylar Bags?

Thickness plays a pivotal role in the performance of printed Mylar bags. In the world of Mylar, 5 mil thickness strikes a perfect balance:

- Sturdy Yet Flexible: At 5 mil, the bag is thick enough to protect its contents from environmental factors while remaining flexible.

- A Universal Choice: This thickness makes the bag suitable for a broad spectrum of products.

- Resilience in Handling: These bags are less susceptible to damage, ensuring safe transport and storage.

What Does 'mil' Mean in Mylar Bags?

In the Mylar bag universe, 'mil' is a key term that helps determine the bag's suitability for various needs.

Understanding 'Mil':

- A Measure of Thickness: One mil equals one-thousandth of an inch, a measurement of the bag's material thickness.

- Impact of Thickness: The mil count directly correlates to the bag’s durability and protective qualities.

- Tailoring to Product Needs: Different products may require different thicknesses for optimal protection and presentation.

In conclusion, customized Mylar bags are more than just a packaging choice; they’re a strategic branding tool. From the possibilities of printing eye-catching designs to customizing with your unique logo, and choosing the right thickness for optimal product protection, Mylar bags offer a blend of utility and marketing potential.

Understanding these elements allows businesses to tailor their packaging to reflect their brand's essence and resonate with their audience. As packaging trends evolve, custom Mylar bag printing stand as a testament to innovative, functional, and impactful design in the world of product presentation.

Leave a comment